Numerical simulation and performance optimisation of in-cylinder friction of cylinder liner and piston ring in internal combustion engine based on deep neural network

and

Mar 17, 2025

About this article

Published Online: Mar 17, 2025

Received: Oct 11, 2024

Accepted: Jan 31, 2025

DOI: https://doi.org/10.2478/amns-2025-0164

Keywords

© 2025 Yichao Qian et al., published by Sciendo

This work is licensed under the Creative Commons Attribution 4.0 International License.

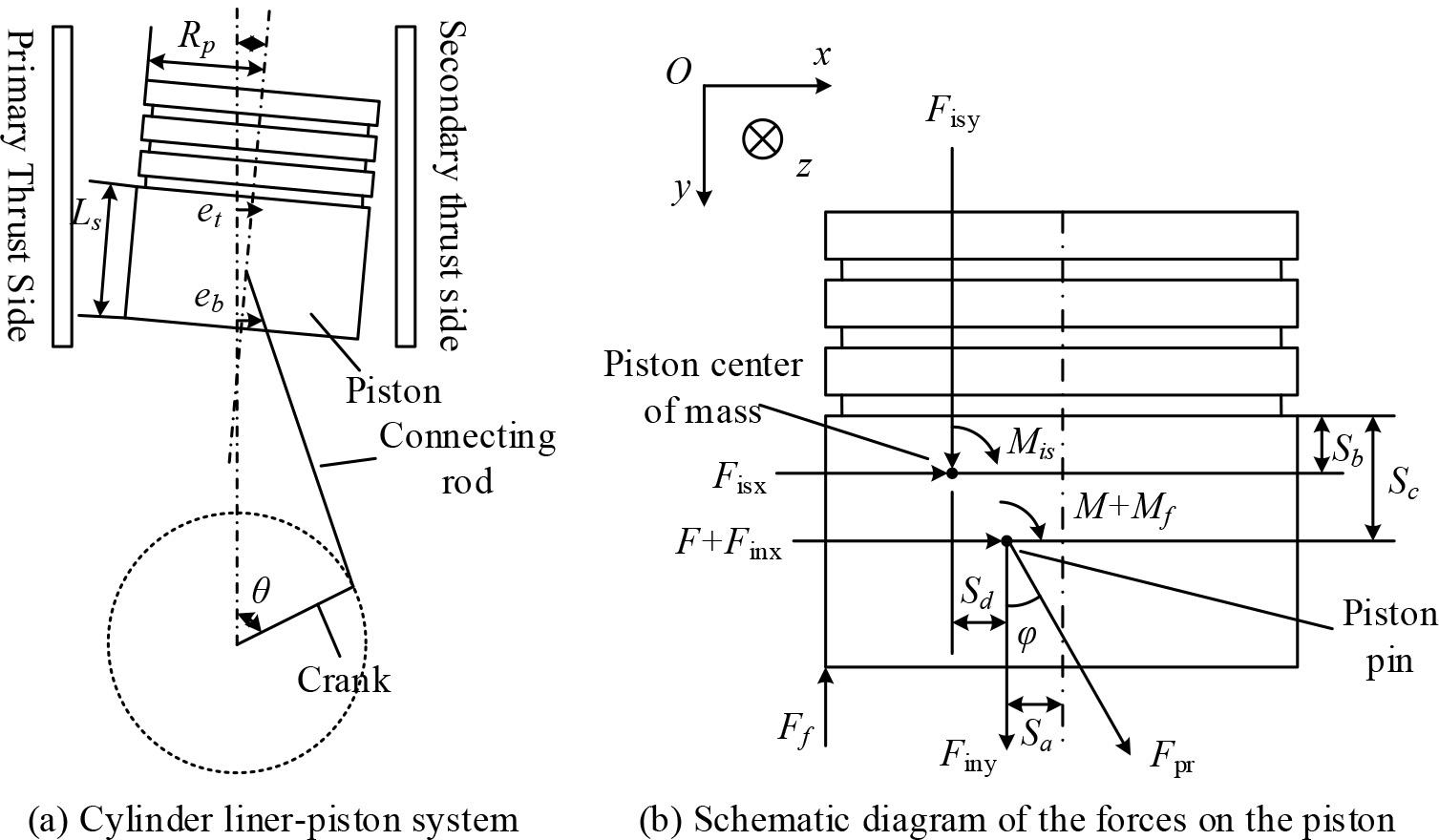

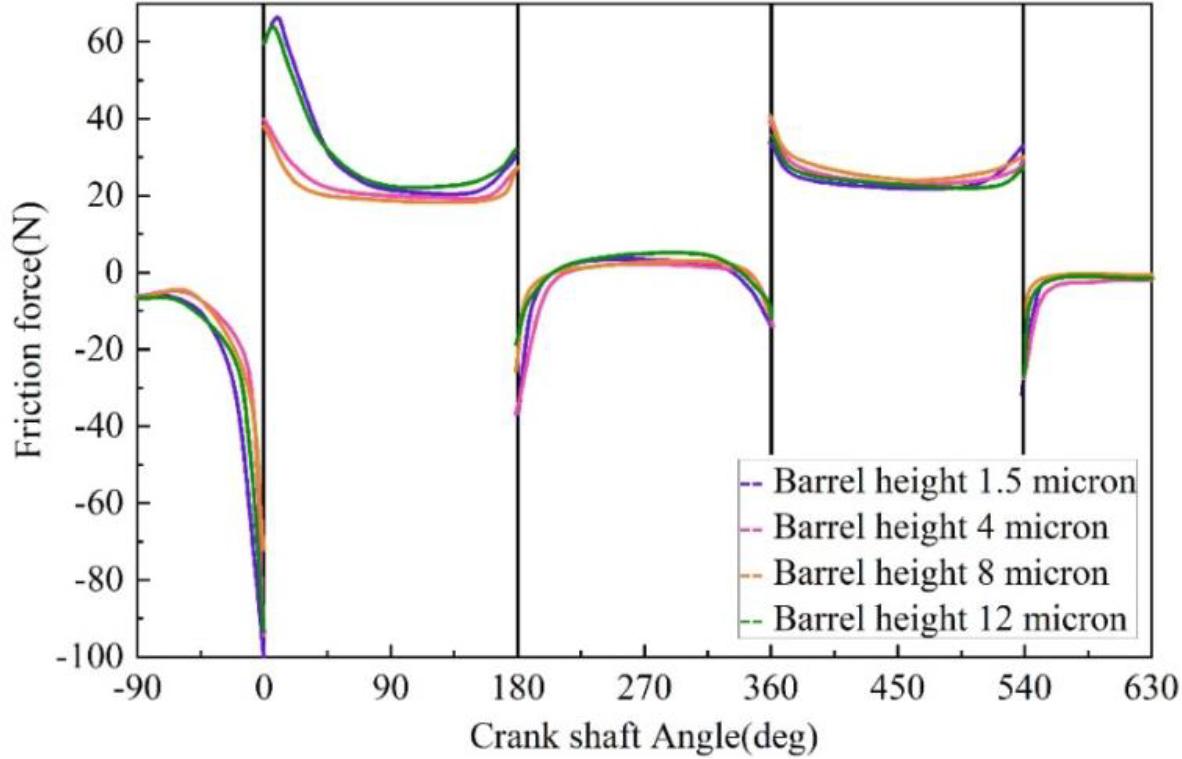

Figure 1.

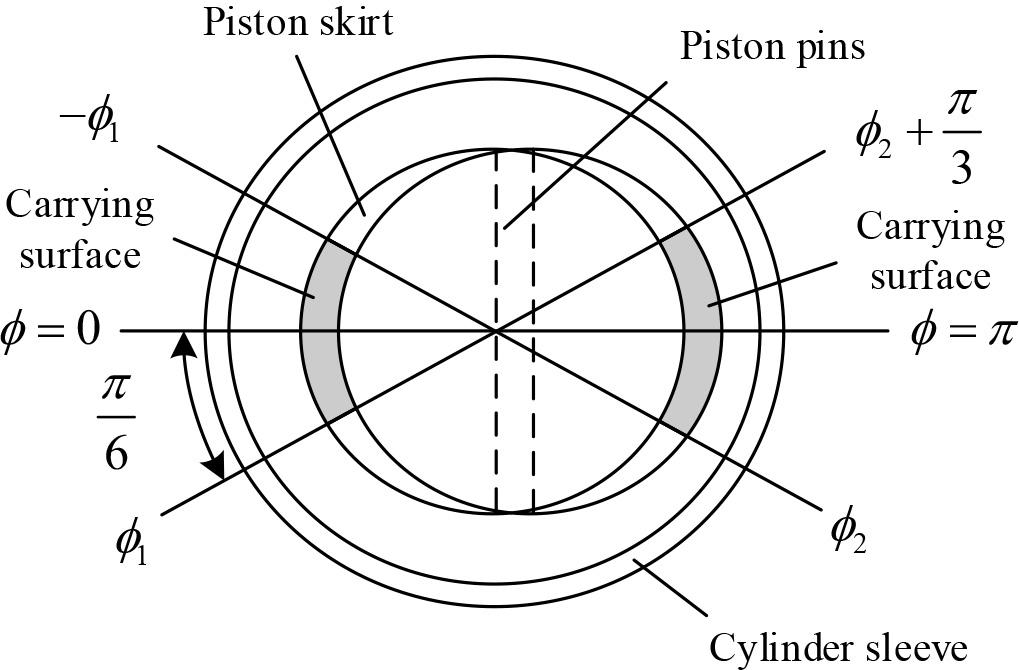

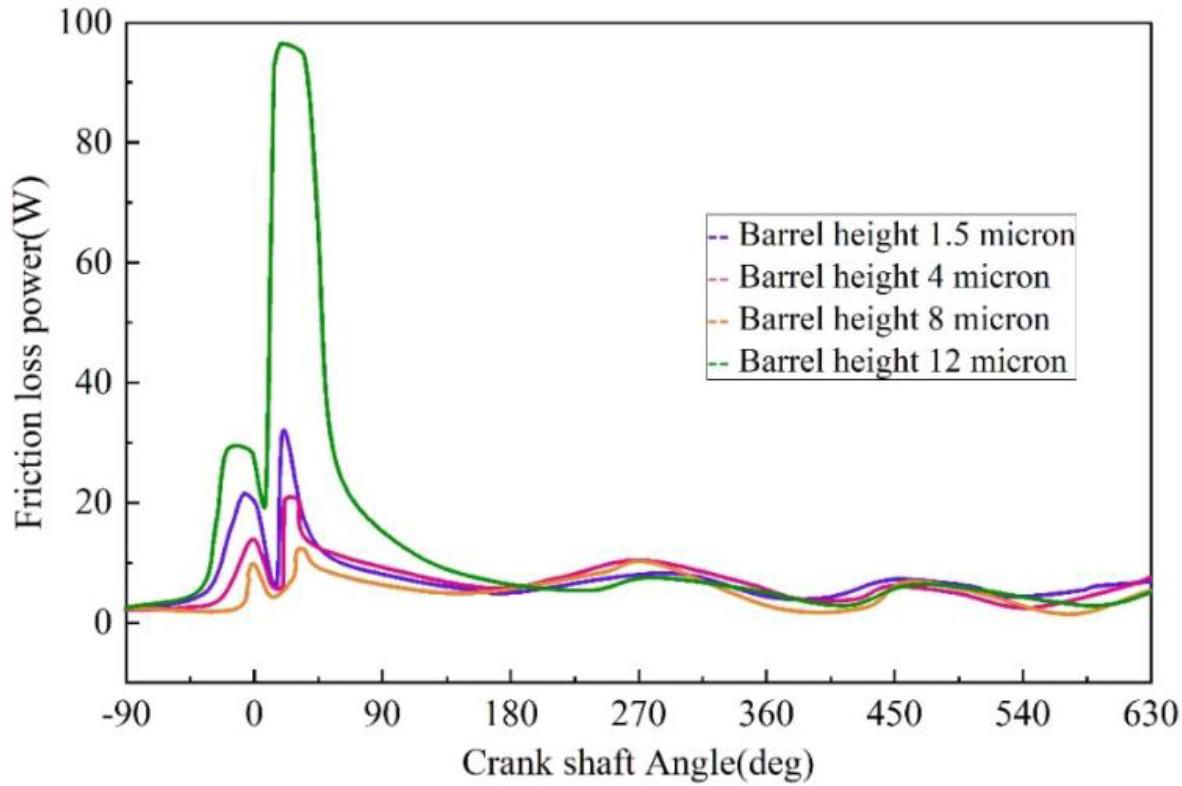

Figure 2.

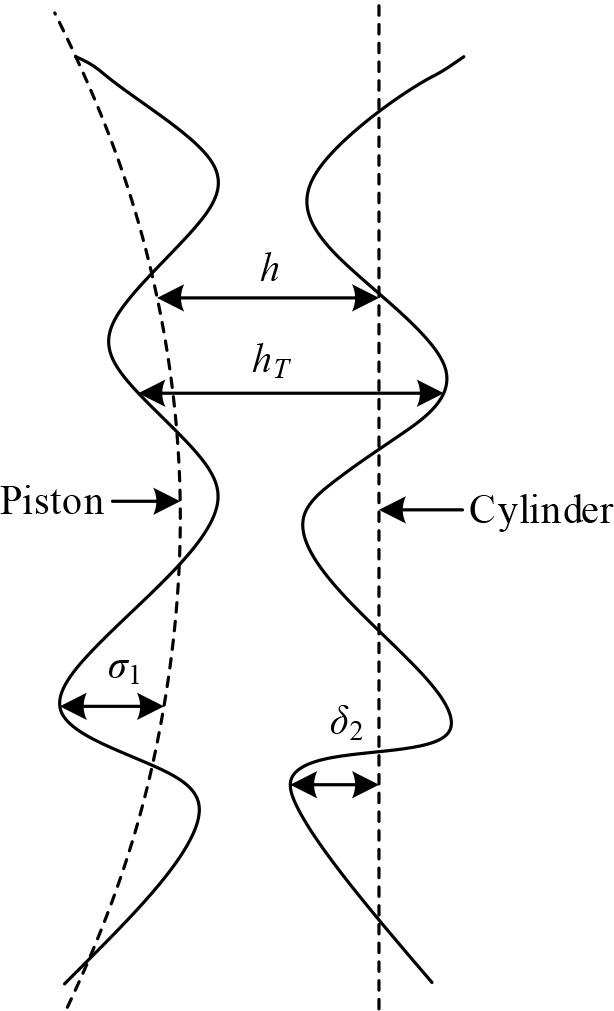

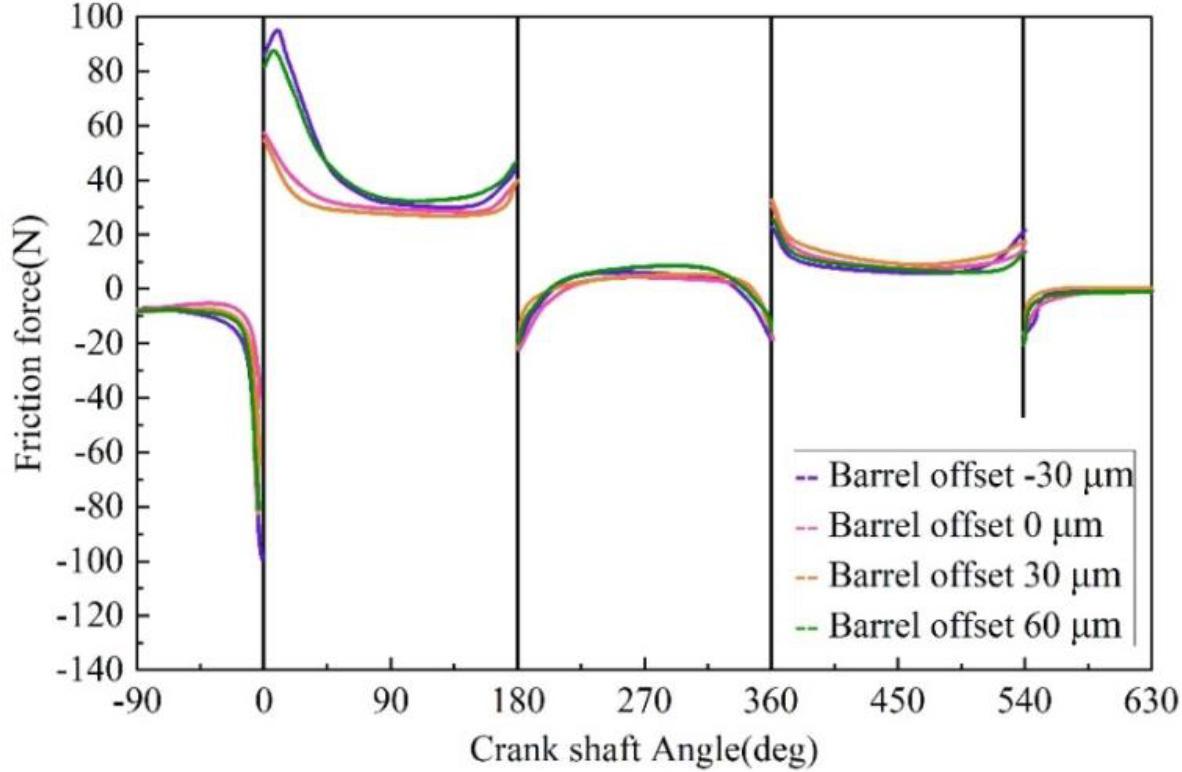

Figure 3.

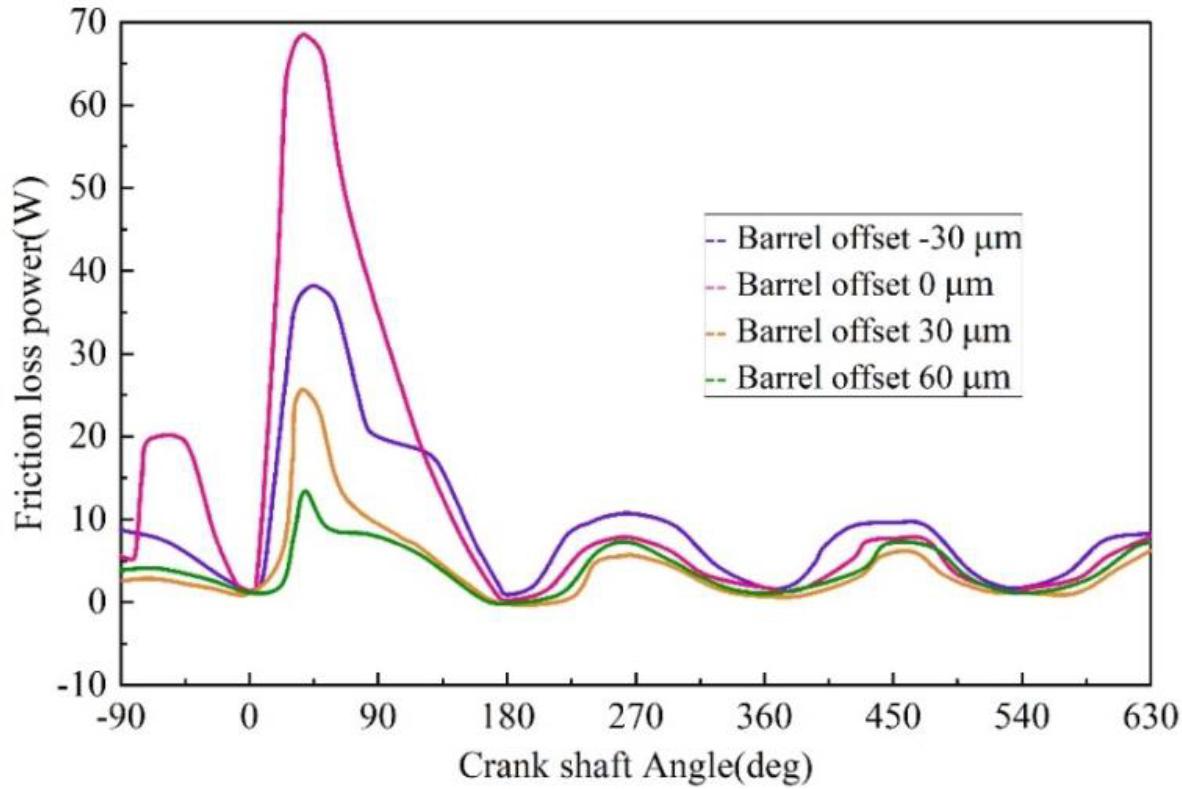

Figure 4.

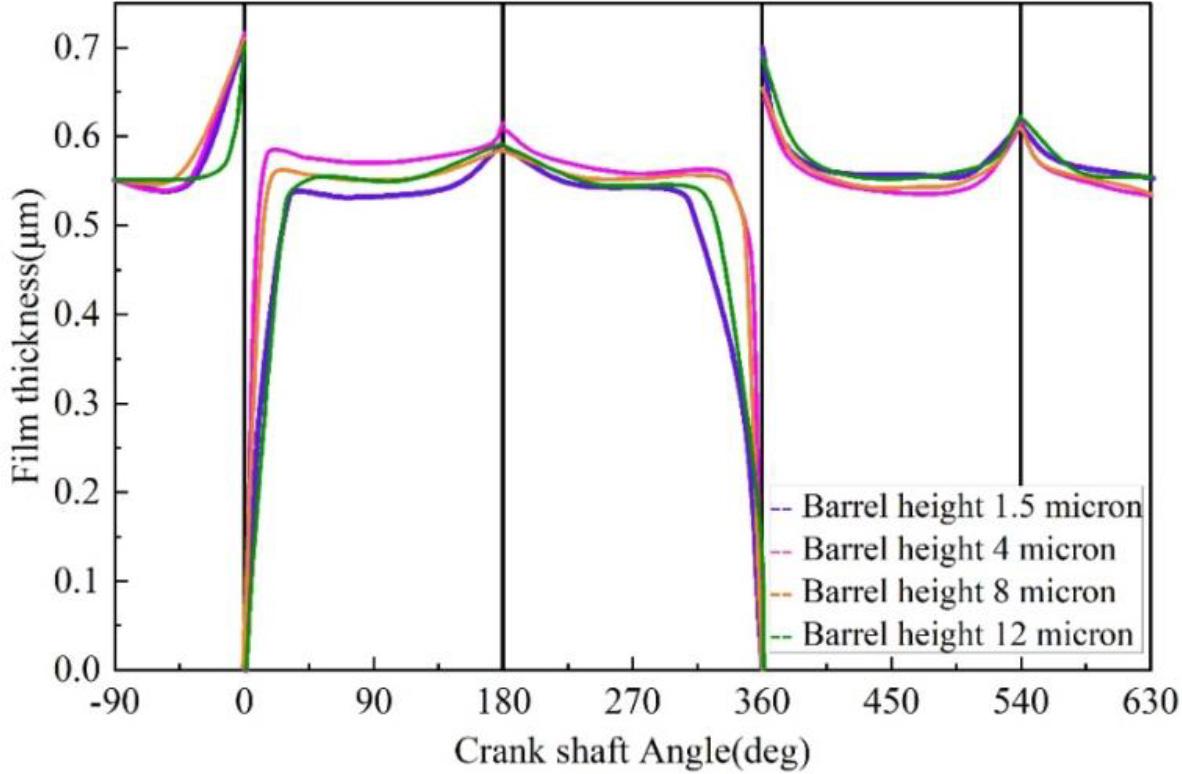

Figure 5.

Figure 6.

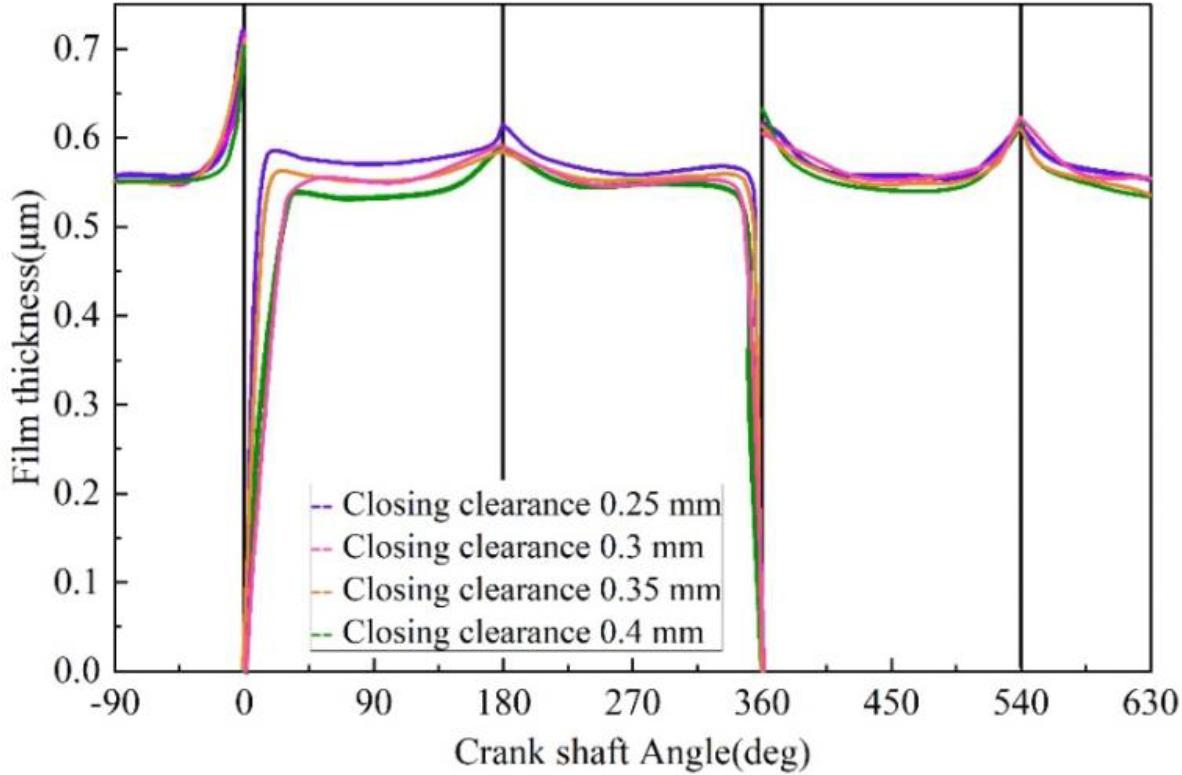

Figure 7.

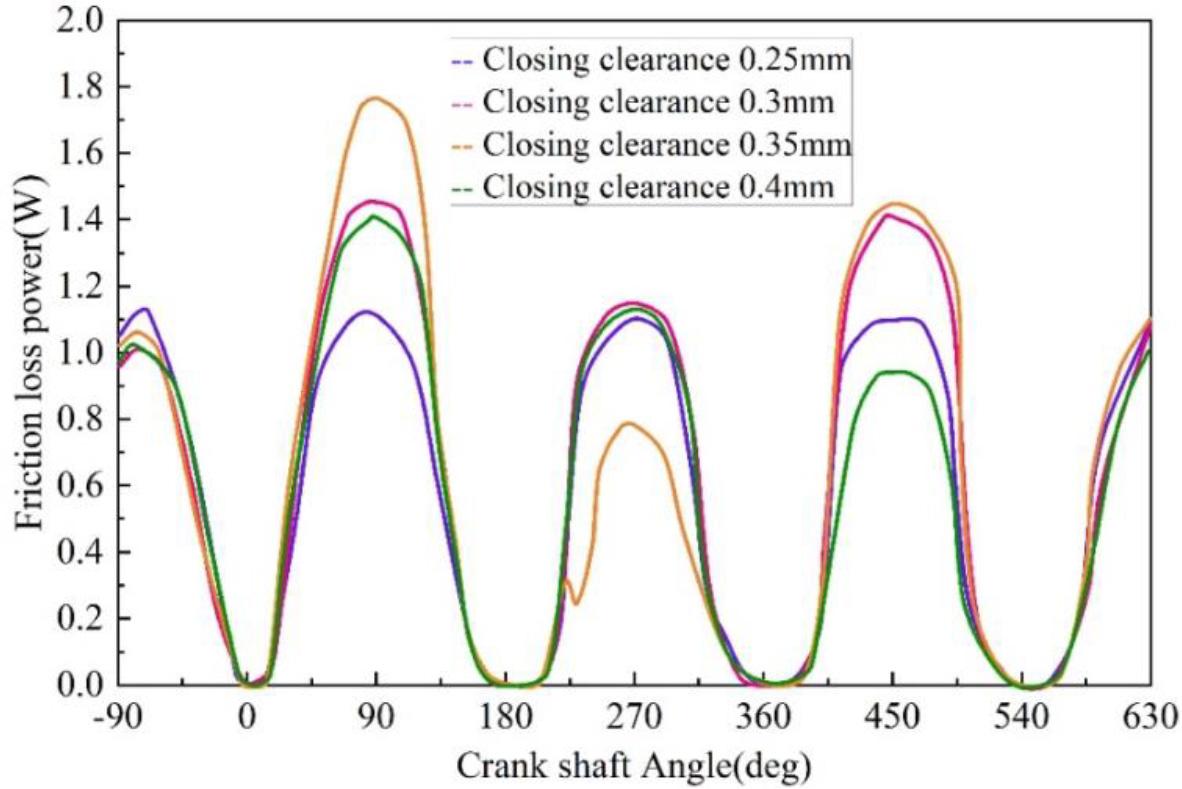

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 12.

Figure 13.

Figure 14.

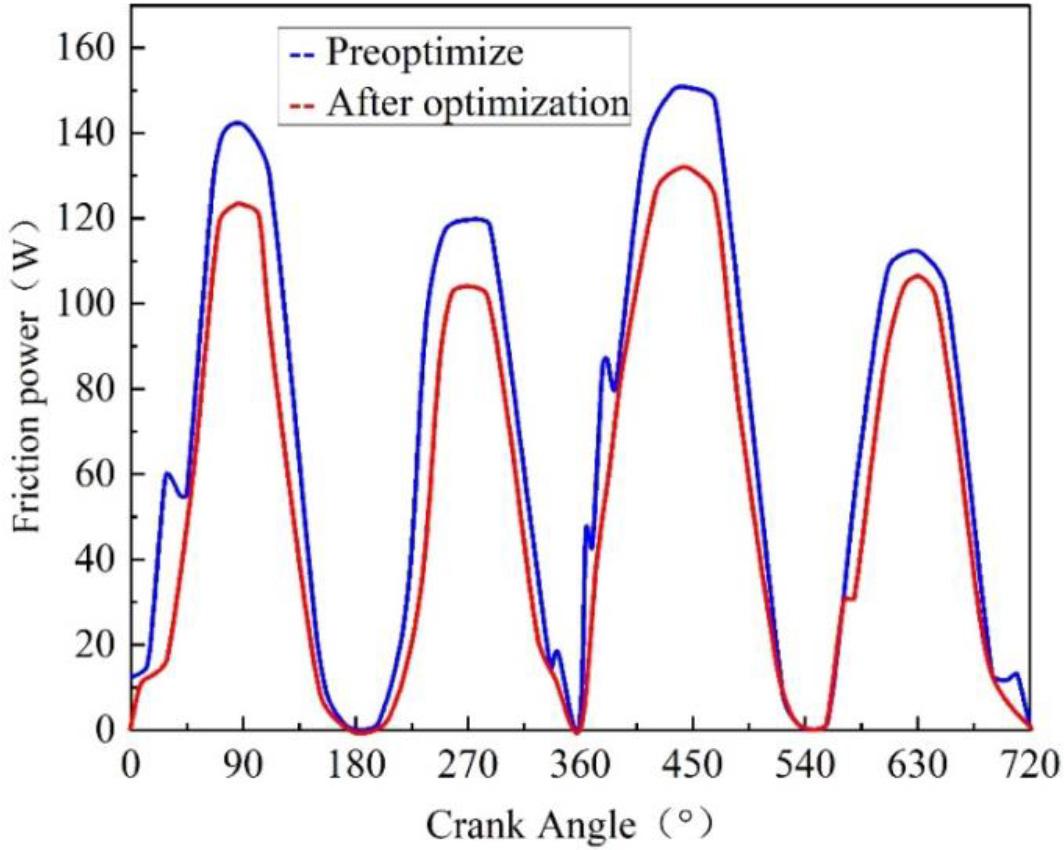

Figure 15.

Figure 16.

Figure 17.

Figure 18.

The difference of each factor and the overall score of each level

| Name | Medium convex point offset | Effective lubrication length (mm) | Barrel height(μm) |

|---|---|---|---|

| Minimum oil film thickness | |||

| First level(i=1) | 1.833 | 1.849 | 1.989 |

| Second level(i=2) | 1.881 | 1.874 | 1.892 |

| Third level(i=3) | 1.934 | 1.917 | 1.78 |

| Aberration R | 0.102 | 0.064 | 0.189 |

| The friction loss of the top ring | |||

| First level(i=1) | 0.332 | 0.311 | 0.306 |

| Second level(i=2) | 0.312 | 0.324 | 0.311 |

| Third level(i=3) | 0.286 | 0.32 | 0.303 |

| Aberration R | 0.038 | 0.001 | 0.004 |

| Minimum oil film thickness | |||

| First level(i=1) | 4 | 3 | 1 |

| Second level(i=2) | 3 | 2 | 2 |

| Third level(i=3) | 2 | 1 | 3 |

| The evaluation index of the friction loss | |||

| First level(i=1) | 4 | 1 | 2 |

| Second level(i=2) | 3 | 3 | 3 |

| Third level(i=3) | 2 | 2 | 1 |

| Top ring type line parameter | |||

| First level(i=1) | 7 | 4 | 3 |

| Second level(i=2) | 5 | 5 | 5 |

| Third level(i=3) | 3 | 3 | 4 |

Orthogonal optimization test factor level of piston ring type line parameter

| Name | Medium convex point offset | Effective lubrication length (mm) | Barrel height(μm) |

|---|---|---|---|

| Level 1 | 10% | 5 | 10 |

| Level 2 | 20% | 5.4 | 14 |

| Level 3 | 30% | 5.8 | 18 |

The original scheme is compared with the proposed scheme

| Name | Medium convex point offset | Effective lubrication length (mm) | Barrel height(μm) | Minimum oil film thickness(μm) | Friction loss work(kW) |

|---|---|---|---|---|---|

| Original plan | Unbiased shift | 2.6 | 18 | 1.431 | 0.295 |

| After optimization | 35% | 4.6 | 10 | 2.051 | 0.282 |

Orthogonal optimization test results of piston ring line parameters

| Name | Medium convex point offset | Effective lubrication length (mm) | Barrel height(μm) | Minimum oil film thickness(μm) | Friction loss work(kW) |

|---|---|---|---|---|---|

| Solution 1 | 10% | 5 | 10 | 1.912 | 0.331 |

| Solution 2 | 10% | 5.4 | 14 | 1.829 | 0.325 |

| Solution 3 | 10% | 5.8 | 18 | 1.762 | 0.332 |

| Solution 4 | 20% | 5 | 14 | 1.859 | 0.312 |

| Solution 5 | 20% | 5.4 | 18 | 1.785 | 0.309 |

| Solution 6 | 20% | 5.8 | 10 | 2.015 | 0.310 |

| Solution 7 | 30% | 5 | 18 | 1.811 | 0.280 |

| Solution 8 | 30% | 5.4 | 10 | 2.021 | 0.289 |

| Solution 9 | 30% | 5.8 | 14 | 1.965 | 0.284 |