Research on the New Construction Industrialization Platform Based on Computing Technology

Online veröffentlicht: 17. März 2025

Eingereicht: 14. Okt. 2024

Akzeptiert: 02. Feb. 2025

DOI: https://doi.org/10.2478/amns-2025-0194

Schlüsselwörter

© 2025 Zhensen Zhang, published by Sciendo

This work is licensed under the Creative Commons Attribution 4.0 International License.

In order to comprehensively meet the development needs of China’s basic construction work and also to ensure that the construction field can meet the industrialized construction standards as soon as possible, it is necessary to strengthen the cognition of industrialized construction technology and make clear the value of industrialized technology for the promotion of the construction mode. Promoting the development of construction industrialization is the main means to prompt the transformation of the production mode of the construction industry from rough to intensive [1].

This paper proposes a new construction industrialization platform based on BIM technology and digital twin computing technology, with a view to promoting the high-quality development of new construction industrialization through this platform.

The application of new construction industrialization computing technology in the construction industry is in full swing. This paper combines BIM technology and digital twin computing technology to construct an intelligent construction management platform applied to the development of new construction industrialization. In this platform, a rectangular piece sampling generation method is designed for building panels, and an isomorphic iterative neighbourhood search algorithm is used to optimize the rectangular piece sampling, which reduces the consumption of building panels and improves the efficiency of rectangular piece sampling and cutting. In addition, digital twin computing technology is integrated into the platform architecture, and multiple sources of data from the construction site are fused using DS fusion algorithms to realise the intelligent identification and safety assessment of key components on the construction site. Finally, the feasibility of the new construction industrialization platform in reducing project construction costs and real-time information collection is analysed, aiming to provide a new development path for the new construction industrialization.

In recent years, although China’s construction industrialization has achieved remarkable progress, the industry inertia demonstrated by the long-adopted rough construction mode is still huge, and the promotion of the transformation and upgrading of construction industrialization is still facing many challenges [2-3]. Industrialized building management systems industrialized building lack systematic management. The relevant government agencies failed to give full play to its big head role, so the overall construction industry can not be relied on, no trace, hindering the development of industrialization in the construction field [4-7]. Industrialized building construction difficulty aspect the industrialized building has higher construction difficulty, the building side through the construction difficulty of the building to balance the balance between industrialized building and the building owner’s personalised needs for the expansion of the scale of industrialized building production [8-10]. In terms of industrialized building expenditure and revenue, the principle of standardised production is inconsistent with the diversified development needs of the industry, and there is a contradiction between the demand for personalised buildings and uniform, standardised building facilities, resulting in a mismatch between input costs and revenue [11-13]. Talent reserves, colleges and universities and related training institutions will not open a special curriculum for the industrialized construction mode, resulting in a lack of construction industry personnel with sufficient practical experience, which affects the development of industrialization in the field of construction [14-17].

The industrialization of China’s construction has become an inevitable development trend for the whole industry, so the relevant practitioners do not need to be overly nervous or reject the new standards and regulations in the industry. Therefore, the existing construction industrialization industry relies on digital and intelligent technology to build an engineering digital ecosystem to provide technical support for the development of China’s new construction industrialization [18-20].

As science and technology continue to advance, China’s industrialization of construction is moving towards a comprehensive new phase. This transformation relies on advanced digital computing technology, which can effectively integrate design, production, and management and can provide better services, leading to higher efficiency, better quality, less energy consumption, and less pollutant emissions. In the context of new construction industrialization, sustainable development is the key direction of change sought by the construction industry today. Based on the digital computing technology to establish the intelligent manufacturing system for new industrialization and relying on the platform to coordinate all types of data in the construction industry, it also provides reliable data support for optimising the development path of the new industrialization while reflecting the concept of sustainable development.

New construction industrialization is driven by a new generation of information technology, with systematic, integrated design, lean production, and construction of the whole life cycle of the project as the main means.Integration of the whole engineering industry chain, value chain, and innovation chain to achieve the industrialization of engineering construction with high efficiency, high quality, low consumption, and low emission. [21].

The new construction industrialization needs to integrate the excellent achievements since the development of industrialization in many aspects and deeply integrate modern information technology through optimisation and unification of all kinds of housing accessories modulus, using fewer specifications, and more combinations of methods to form standardised parts and components. And through the integration of intelligent mechanized construction as a means to achieve component factory production, assembly installation, and construction. At the same time, it emphasises the integration of design, materials, construction and other production relations in the upstream and downstream chains during the whole life span of the project so as to maximally and comprehensively improve the quality, performance and quality of the project. It realises high efficiency and low energy consumption of construction products, promotes the enhancement of scientific and technological innovation capacity of the construction industry, and realises green, energy-saving and high-quality sustainable development of the construction industry.

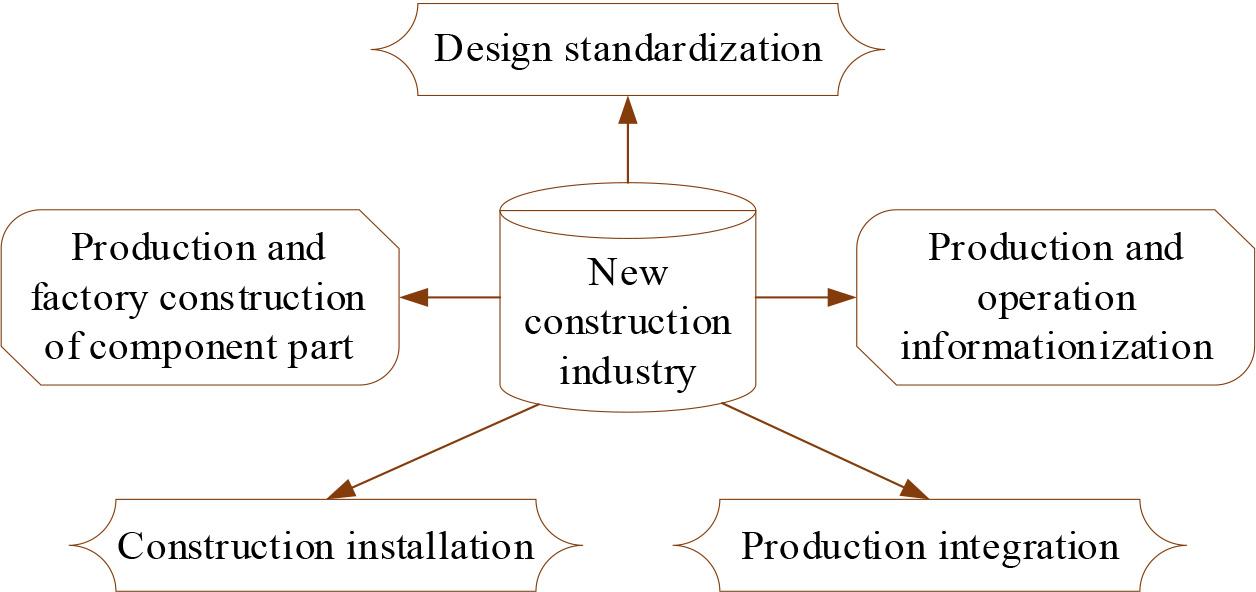

The characteristics of the new construction industrialization are shown in Figure 1, which mainly contains design standardisation, parts production factory, construction and installation assembly, production and management informationisation, and production integration. Through the standardised architectural design, it can effectively reduce the production cycle of the products, and at the same time reduce the production cost, and at the same time effectively improve the predictability of the products, effectively control the defective problems of the products, and improve the production efficiency, so as to enable the enterprises to obtain higher profits. The factory production of parts effectively improves the mechanisation level of building construction, reduces the amount of on-site construction, effectively reduces the amount of labour used and the intensity of work, and improves construction efficiency.

Characteristics of new construction industry

In addition, in the mode of construction and installation assembly, the amount of wet work on site can be greatly reduced, thus increasing the speed of construction while reducing the number of construction personnel and reducing the waste of materials. At the same time, the safety and energy-efficient performance of the building can be effectively improved in this way.The new construction industrialization can make full use of production information and achieve efficient application of information, so that the advantages of construction industrialization can be brought into play. In order to give full play to the role of new construction industrialization, it is necessary to achieve the orderly connection of design, manufacturing and construction processes, which requires the integration of relevant technologies and standards to achieve the integration of production.

Building information modelling (BIM) is based on building project drawings, scaled down to a certain proportion, and then establishing three-dimensional graphics of construction projects, using advanced information technology, the combination of reality and reality, to establish a consistent building information base for the actual building project [22]. BIM contains not only the geometric contours of the building components and component attributes, but also the component objects of the reinforcement, costing, and other information. Intuitively seeing the 3D information model of the building, integrating architecture, structure and costing into one, it greatly improves the degree of information integration of construction projects and provides a platform for information sharing and exchange. Applying BIM technology to the industrialization architecture of new buildings is a major trend in the development of new construction industrialization and integration.

For new construction industrialization, the BIM model alone is not sufficient.The BIM model only provides the basis and conditions for building industrialization, but cannot provide real-time dynamic data of the building during operation and maintenance. Through the introduction of Internet of Things technology, to open the data barriers, the BIM model and the real-time dynamic data of the equipment in the building to bind one by one, to achieve real-time operation and maintenance control of the building. In the intelligent manufacturing of building industrialization, digital twin technology is the integration of real-time dynamic data with the BIM model, which is reflected in the accurate mapping of the BIM model with the facilities and equipment and the integration and sharing of building dynamic data.

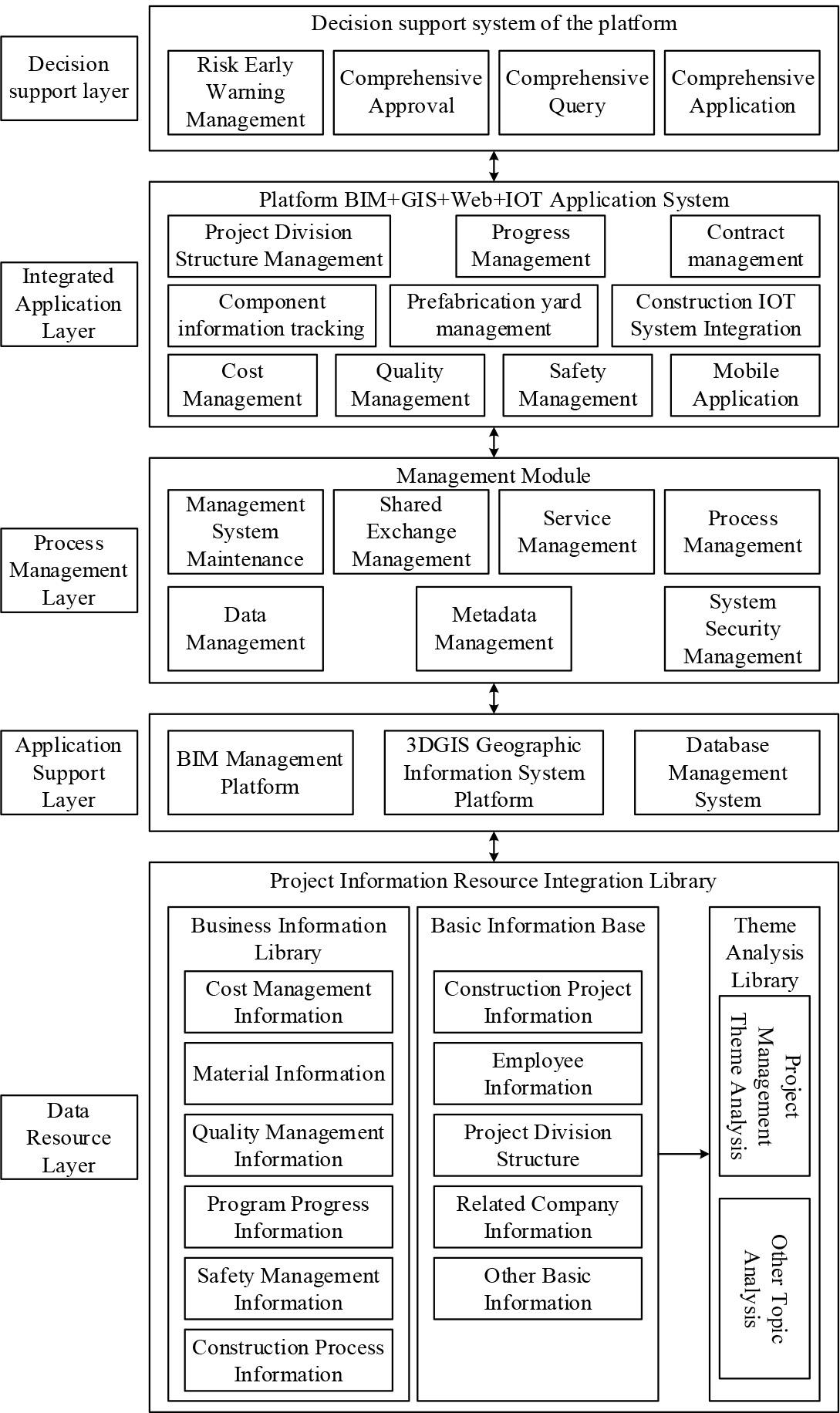

The intelligent management platform for new construction industrialization is established based on BIM technology and combined with digital twin technology, as shown in Figure 2. It adopts Revit as the BIM platform, Stamp GIS as the GIS platform, and on the basis of the Revit model library and digital twin, the programming languages of JavaScript and C# are selected, combined with Visual Studio.net for software development [23]. It is able to provide a variety of tools, a clear and concise graphical user interface, and a simple way to access data. The underlying modules of the platform are developed using VC++ dynamic connection library. The overall architecture is divided from bottom to top into a decision support layer, integrated application layer, process management layer, application support layer and data resource layer, which needs to be created in a distributed and multi-layered manner during model creation to ensure the flexibility of data call combinations.

Framework of the new construction industrialization platform

The new construction industrialization intelligent management platform based on BIM and digital twin, which is derived from the static structured data of topography and landforms, buildings under construction, plus the dynamic, unstructured data of site IoT, provides an overlay computation capability and platform for the data. The new construction industrialization intelligent management platform mainly consists of five systems, namely model interaction, technology management, quality management, safety management, and progress management. The five systems work in coordination with each other to achieve more efficient and high-level intelligent management of construction in terms of technology, safety, quality, and progress under the premise of ensuring smooth loading and browsing of models with large data volumes.

The construction industry is one of the industries that have accompanied the development of human history for the longest period of time and is the pillar industry of the national economy in most countries.In order to promote supply-side structural reform in the construction industry and provide high-quality construction products to the entire society. Relying on digital computing technology, the new construction industrialization intelligent management platform has been established, with the help of which building construction safety, cost management, intelligent manufacturing design and so on can be achieved. The new construction industrialization intelligent platform is the main means to prompt the change of the production mode of the construction industry from rough to intensive and is also the implementation path to achieve the high-quality development of new construction industrialization.

The construction manufacturing sector consumes a large amount of sheet metal for the production of various parts. The search for an optimal materialisation scheme can increase the utilisation rate of building materials and reduce the production cost, whereas manual nesting is time-consuming and labour-intensive, and the utilisation rate of building materials is not high. The design of an optimized building sheet feeding algorithm automatically generates the feeding scheme, which not only saves time in scheduling but also improves the utilisation rate of the building sheet. In this paper, on the new construction industrialization intelligent platform, the design of rectangular pieces of intelligent nesting optimisation algorithm to provide support for saving construction production costs and improve the utilization rate of building panels.

The four-block sampling method is to divide the building panels into four rectangular blocks with one parent dividing line and two child dividing lines, to discharge strips of the same direction and length in each block, and to discharge the same kind of rectangular pieces in the strips. According to whether or not there is a constraint on the number of each rectangular piece allowed to appear in the sampling method, the corresponding sampling algorithms can be divided into unconstrained sampling algorithms and constrained sampling algorithms [24]. The unconstrained sampling algorithm has no constraints on the number of rectangular pieces allowed to appear in the sampling method, and the constrained sampling algorithm limits the number of rectangular pieces allowed to appear in the sampling method to no more than its upper bound. In this paper, we design the constrained rectangular piece sampling algorithm as follows:

Assume that the upper bound on the number of rectangular pieces of type

Let

For vertical strip

For block

The above model is a bounded knapsack problem, which is solved by counting the number of rectangular pieces of each type contained in block

Take the lower left corner of the plate as the coordinate origin, the horizontal edge as

The objective function of model (5) is to maximise the value of the scheduling approach and the constraint is that the number of each rectangular piece in the scheduling approach does not exceed its upper bound.

In order to achieve the maximum utilisation of building panels and relatively high efficiency in the process of rectangular piece scheduling, this paper proposes an iterative neighbourhood search algorithm for solving the optimal discharge order of small rectangles and their scheduling scheme. The discharge order of rectangular pieces is regarded as a certain arrangement of rectangular piece numbers, which is used as an encoding, and the blank rectangle filling algorithm is used to decode the sampling scheme and the sampling utilisation rate [25].

Denote

The process of the iterative neighbourhood search algorithm is to use the above two kinds of neighbourhood operators to continuously iterate, alternately searching the solution space, i.e., after a certain number of consecutive searches by one kind of neighbourhood operator (known as the maximum number of local searches

In the iterative neighbourhood search algorithm, in order to control the search time of the algorithm, a global maximum number of searches

Notations

“Random selection of operator execution point (

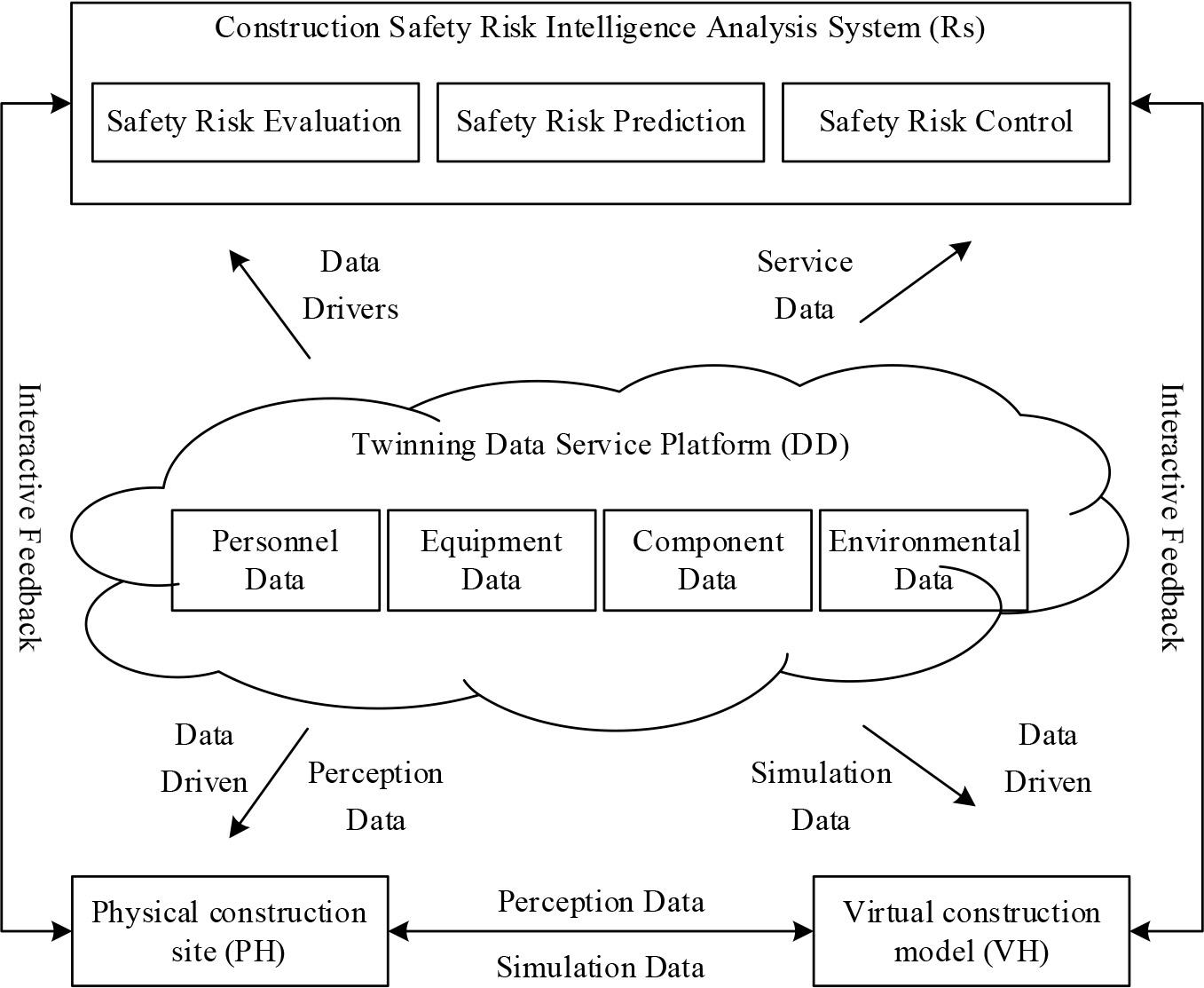

Structural construction process is a dynamic and complex system, combined with the characteristics of structural construction safety risk management and application needs, define the digital twin five-dimensional model for structural construction safety analysis, as shown in Equation (6), and propose the digital twin framework for intelligent analysis of structural construction safety as shown in Figure 3.

Structure construction safety analysis framework

Where

The physical construction site is the data source that drives the operation of the digital twin model and is the basis for building the corresponding virtual digital twin model [26]. According to the construction safety risk indicator system, the task of physical construction space modelling is to extract the physical entity information related to the safety risk factors by configuring the information collection and transmission devices. Specifically, the physical elements of the construction site are operators, tower crane equipment, prefabricated components, and the site environment.In addition, the level of safety risk management needs to be measured by the policy and institutional situation on site. Therefore, the physical construction site model is described as:

The prerequisite for realising the intelligent assessment of safety in the construction process is to ensure the dynamic perception of the virtual and the real. In the real construction environment, the first step is to arrange the sensors to monitor the structural performance, and the fusion of the measured data from the sensors and the simulated data from the twin model drives the intelligent diagnosis and scientific prediction of the structural safety performance. However, the sensor arrangement is optimised to facilitate data transmission and processing at a later stage. The target parameters measured by the sensors are set as:

Then the maximum error is:

The objective function of sensor arrangement can be derived from the maximum error, i.e.

In addition, according to the structural reliability analysis, the guaranteed structural safety performance should comply with

In turn, the safety performance of the structure is intelligently analysed in real time.

For the verification results of building construction safety, this paper proposes the verification evaluation coefficient EV value, by which the EV value can not only indicate whether the recognition effect is correct or not, but also indicate the stability of recognition. It is expressed as:

The construction industry is the cornerstone of economic development. In order to achieve the high-quality development of new construction industrialization, this paper combines BIM technology and digital twin technology to establish a new construction industrialization platform, with the help of digital information control of the intelligent platform, in order to achieve the positive hybrid effect through the synergistic effect of the two and to create a greater benefit in the construction of building engineering projects. And this is used as a basis to promote the high-level development of new construction industrialization, and to provide assurance for enhancing the intelligence and economic benefits of the new construction industry.

The purpose of designing the optimisation algorithm for rectangular piece nesting in a new construction industrialization platform is to improve the intelligent manufacturing efficiency as well as the utilisation of building panels during the construction of rectangular pieces. For this purpose, this paper splits the large rectangle of 150*150 into multiple small rectangles of the same size, and there are height lower bounds for both strip width and optimal solution, which will thus be used as a perfect data set.

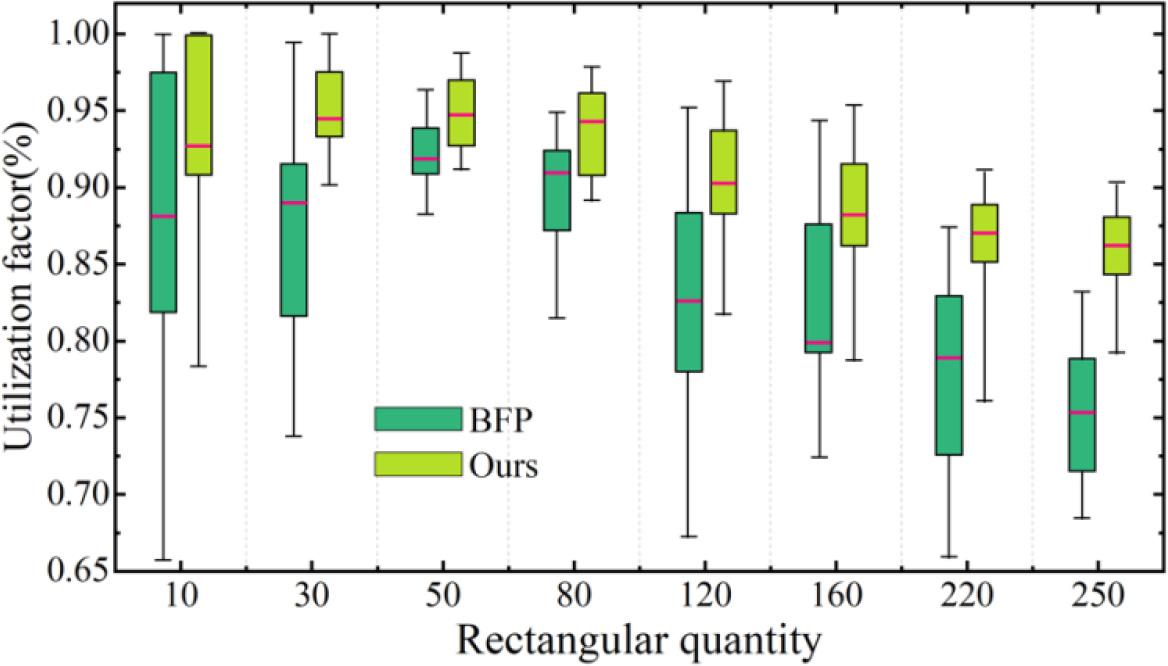

In this paper, a constructive heuristic algorithm (BFP) is chosen as the comparison algorithm. Both algorithms have the same parameter settings, and the algorithm implementations are implemented on the same machine configuration using Python language.On the constructed perfect dataset, 100 tests are performed on different numbers of instances with different numbers of rectangles, and both algorithms are evaluated by strip utilisation and running time. The results are shown in Table 1; the best results are highlighted in bold, and the average performance of all the instances is given in the last row. Figure 4 shows the utilization box-and-line plots for the two algorithms.

Performance comparison of two algorithms

| No. | Average | Worst | Best | STD. | Time(ms) | |||||

| BFP | Ours | BFP | Ours | BFP | Ours | BFP | Ours | BFP | Ours | |

| 10 | 0.879 | 0.563 | 1.000 | 0.095 | 2.48 | |||||

| 30 | 0.883 | 0.689 | 0.985 | 0.043 | 4.24 | |||||

| 50 | 0.918 | 0.672 | 0.973 | 0.031 | 7.51 | |||||

| 80 | 0.906 | 0.661 | 0.972 | 0.065 | 9.65 | |||||

| 120 | 0.823 | 0.623 | 0.959 | 0.073 | 13.37 | |||||

| 160 | 0.807 | 0.635 | 0.931 | 0.066 | 18.73 | |||||

| 220 | 0.792 | 0.628 | 0.971 | 0.065 | 42.19 | |||||

| 250 | 0.776 | 0.631 | 0.969 | 0.082 | 103.26 | |||||

| Means | 0.848 | 0.638 | 0.970 | 0.065 | 25.18 | |||||

The utilization ratio of the two algorithms

Specifically, for instances with 10 rectangles, both algorithms can achieve an optimal utilisation rate of 1.0, mainly due to the fact that the optimal solution is also easily selected by the greedy rule with a small solution space. The average and worst utilisation of the algorithms in this paper are 0.908 and 0.737, which are 7.08% and 15.52% higher than the BFP algorithm, and the standard deviation is also much lower than that of BFP. With the increase in the number of rectangular pieces, this advantage will be more obvious, which shows that this paper’s algorithm provides better scheduling utilisation and stability for the intelligent manufacturing of rectangular pieces for new construction industrialization buildings. From the point of view of runtime efficiency, the average time for this paper’s algorithm to optimize rectangular parts sampling is 25.18ms, which is about 1.7 times longer than that of the BFP algorithm. This is because the preprocessing of the packing state and the model inference are needed for the optimisation of the rectangular part sampling, which consumes more time than the BFP algorithm, but the results obtained are better than the BFP algorithm. Therefore, from a comprehensive point of view, this paper combines the iterative neighbourhood search optimization algorithm with the rectangular piece sampling algorithm with certain feasibility and efficiency, which can provide a reference for the intelligent construction and efficiency optimization of the new building industrialization.

In order to verify the application feasibility of the iterative neighbourhood search algorithm proposed in this paper in the optimization of rectangular pieces, the rectangular pieces of a building materials steel structure processing plant are selected as an example to carry out an instance analysis. The processing plant needs to cut a batch of rectangular plates for the assembly of steel components because the project requires a large number of components, a variety of types, so from the order selected a batch of 12 types of each of the 10 pieces, a total of 120 rectangular pieces as the experimental object. Table 2 displays the size and number of rectangular pieces, with the raw material plate being 2000mm wide and not limited in height.

The size and number of rectangular parts

| No | Material | Length/mm | Width/mm | Quantity |

| 1-A1 | Q345B | 880 | 200 | 10 |

| 1-A2 | Q345B | 580 | 500 | 10 |

| 1-A3 | Q345B | 185 | 350 | 10 |

| 2-B1 | Q345B | 250 | 260 | 10 |

| 2-B2 | Q345B | 1200 | 210 | 10 |

| 3-C1 | Q345B | 340 | 790 | 10 |

| 3-C2 | Q345B | 120 | 215 | 10 |

| 4-D1 | Q345B | 450 | 235 | 10 |

| 4-D2 | Q345B | 1000 | 565 | 10 |

| 4-D3 | Q345B | 400 | 180 | 10 |

| 5-E1 | Q345B | 180 | 340 | 10 |

| 5-E2 | Q345B | 830 | 420 | 10 |

Optimisation is carried out using Genetic Algorithm (GA), Tent-Genetic Algorithm (TGA), Tent-Genetic Annealing Algorithm (TGSA), Grey Wolf Algorithm (GWO), Tent-Grey Wolf Algorithm (GWO), Discrete Sparrow Search Algorithm (DSSA), Tent-Discrete Sparrow Search Algorithm (TDSSA), and this paper’s algorithm, respectively, and the optimisation results will be comparatively analysed to Verify the effectiveness of this paper’s algorithm in optimising the sampling of rectangular pieces when there are more types. The parameter settings of the algorithms used for the comparison experiments are identical.In order to prevent the influence of algorithmic chance, each algorithm is run 50 times and compared to the raw material utilization rate and scheduling time after optimization. Table 3 shows the comparison results of optimal scheduling for different algorithms.

The optimal comparison results of different algorithms

| Algorithm | Utilization ratio (%) | Utilization standard deviation (%) | Schedule time (s) | Schedule time Standard deviation (s) |

| GA | 87.24 | 0.92 | 582.1 | 6.42 |

| TGA | 88.06 | 0.88 | 574.9 | 7.23 |

| TGSA | 89.75 | 0.73 | 579.8 | 8.37 |

| GWO | 90.38 | 0.69 | 552.4 | 9.04 |

| TGWO | 91.24 | 0.54 | 554.3 | 8.45 |

| DSSA | 89.48 | 0.47 | 558.6 | 4.31 |

| TDSSA | 92.51 | 0.51 | 452.4 | 5.26 |

| Ours | 96.79 | 0.48 | 489.5 | 6.18 |

Based on the iterative neighbourhood search algorithm, the utilisation rate of building materials rectangular plate sampling is 96.79%, and the sampling time is 489.5s, which is 4.28% higher than that of the TDSSA algorithm, which is the second-best performance, and 37.1s increase the scheduling time. Therefore, the algorithm of the present paper is better than GA, TGA, TGSA, GWO, and TGWO in terms of utilisation rate and scheduling time, even though there is a slight increase in scheduling time compared to the TDSSA algorithm. Although there is a slight increase in sampling time compared to TDSSA, it is significantly better than TDSSA in terms of sampling utilisation. Therefore, the neighbourhood iterative search optimisation algorithm proposed in this paper maintains high stability in optimising the sampling problem for a large number of rectangular pieces, and its application to the new construction industrialization platform can realise the intelligent sampling optimisation of the building panels and provide technical support for the saving of building material costs.

The method proposed in this paper aims to improve the safety of construction by dynamically identifying critical components during the construction process, so the following example is designed to verify whether the method can accurately identify the critical components during the construction process. The validation method is to simulate the damage of a member by changing the cross-sectional area and modulus of elasticity. In a certain construction phase, the cross-sectional area and modulus of elasticity of one or several members are reduced directionally while all other conditions remain unchanged, and the member whose parameters have been changed will definitely be the damaged member, which is also the critical member in that phase. Then, the method of this paper is fully automated to identify these members, and if the construction safety intelligent analysis framework supported by Digital Twin can accurately identify these members, it means that the method of this paper is feasible.

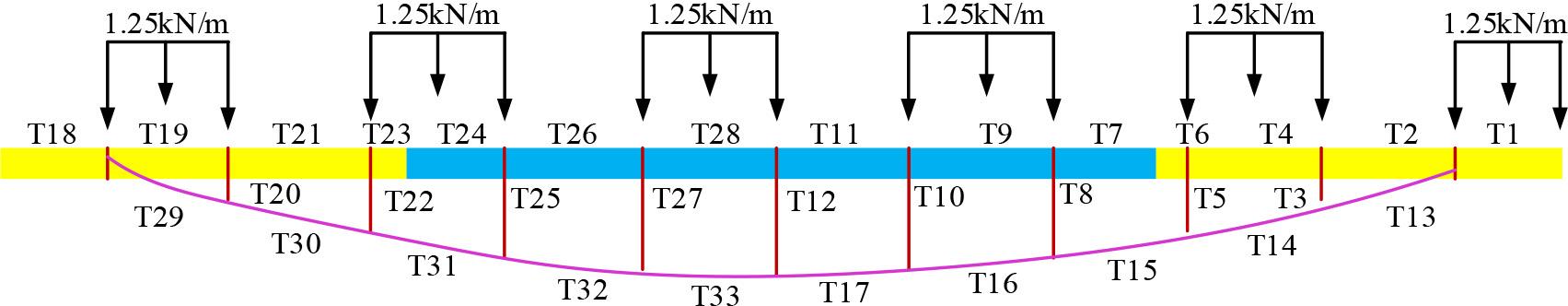

The steel roof cover of a convention and exhibition project in T city, Fujian province is used as the research object, and one of the planar chord-bearing structures is selected as the computational model. The span is 50m, the droop is 3.5m, and the number of braces is 10. The top chord beam is composed of H-beam Q355B, while the spacers are composed of round steel pipe Q245B, and the lower chord cable is composed of prestressing strands with high strength and low resistance. The boundary condition of this string-supported beam structure has a hinged bearing at one end, and a sliding bearing at the other end that releases the restraint along the long axis to release the temperature action, so the effect of temperature action can be disregarded in the analysis. It is assumed that the roof slab system has not fully formed at this stage of the analysis, so the wind load effect is not considered at this time.The unit numbering of the chord-supported beam structure and the load arrangement for validation calculations are shown in Fig. 5.

Verification example component number diagram

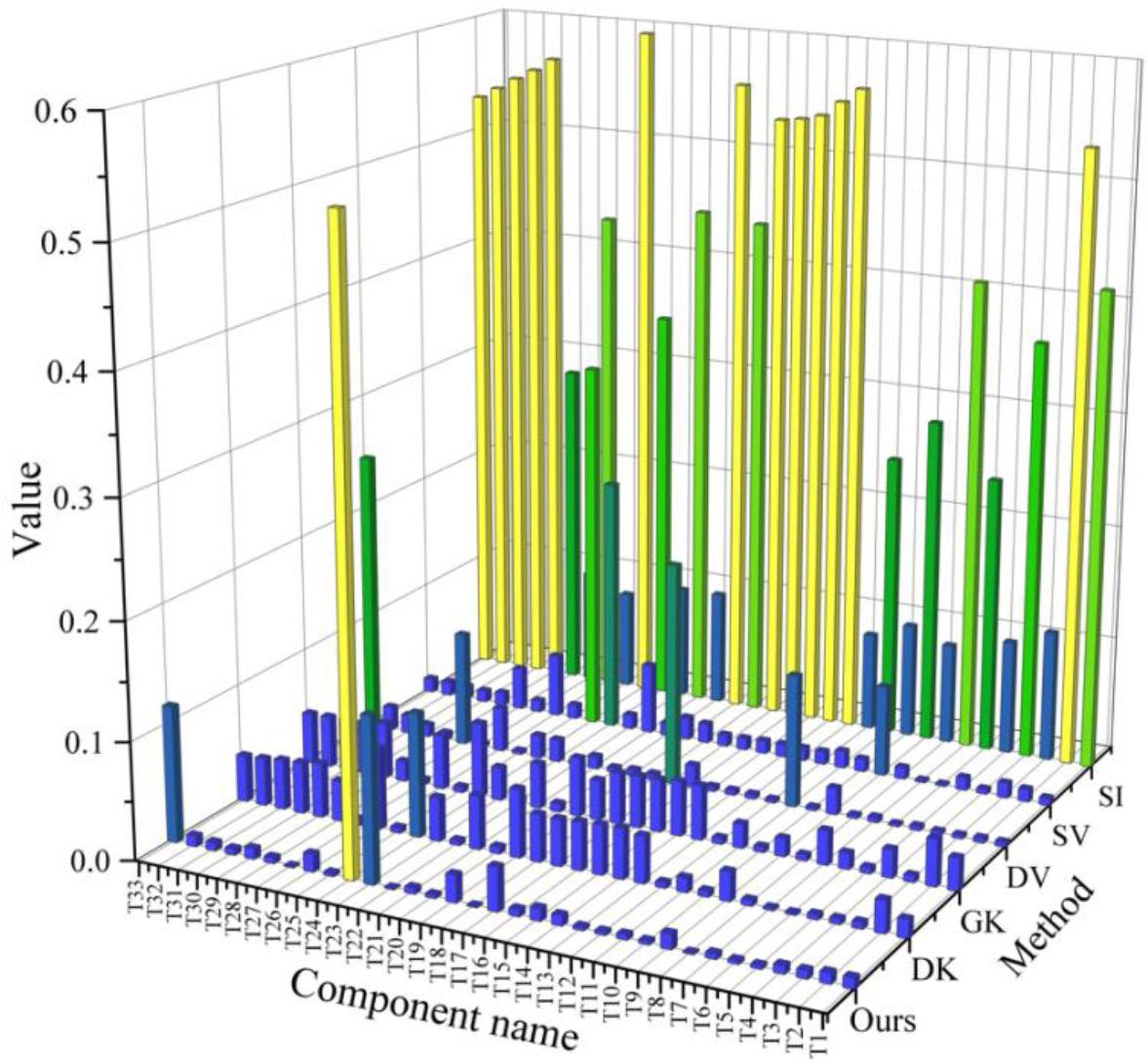

Based on the intelligent analysis method of structural construction safety established by the integration of digital twin technology in the previous section, the key components under different working conditions in the construction process can be accurately identified from the eigenvalue indexes of stress intensity coefficient (SI), stress variation coefficient (SV), displacement variation coefficient (DV), ground state key coefficient (GK), dynamic key coefficient (DK), etc., respectively.

In the analysis process, the structural self-weight condition is taken as the base state of the structure, and the construction process arrangement of the roof (i.e., the structural arrangement of the constant load) is taken as the state of the structure at the first moment of the analysis. According to the load code, the constant load in this study is based on 120kg/m2. Since the construction process requires temporary construction loads of 60kg/m2 to be temporarily arranged in the half-span area, this phase is used as the first moment to analyse the state of the structure. Firstly, the twin data before and after this stage are generated based on the twin model using finite element software calculations, and then the twin data and the sensed data on-site are input into the data processing centre together, and a series of calculations such as eigenvalue extraction is carried out automatically by the D-S fusion algorithm. And the results of fusion decision-making are output to the application management platform, where managers or operators are able to visually and dynamically view the key components analysed and identified, thus realizing the intelligent management of construction safety.

Figure 6 shows the identification effect of each eigenvalue index on the key stress components under the action of temporary construction load. Through the analysis results, it can be found that the T24 and T23 units of the upper steel beam corresponding to the chord support beam under the condition of half-span temporary construction load are the key safety components, that is, the variable cross-section of the steel beam is the most unfavourable position for safety under this condition, which needs to be paid attention to. The EV values calculated by the D-S fusion algorithm in the digital twin intelligent analysis framework are 0.914 and 0.758, respectively, which show very obvious directionality. In addition, T33 and T17 member cells are also highly critical, which suggests that the tension cable deformation in the span is another potentially critical member. Although a single eigenvalue can also present this result to a certain extent, it can be found from the distribution of SI~DK that the accuracy and directionality of a single eigenvalue are far less than the result of data fusion judgement by digital twin, which indicates that the introduction of digital twin technology for data fusion in the new construction industrialization platform can effectively improve the utilisation rate of the data and the relevance and efficiency of decision-making.

Security key component recognition results

In summary, the key safety components under temporary construction loads are the variable section of the steel beams and the mid-span tension cables, respectively, and attention should be paid to the monitoring and maintenance of the corresponding steel beams and tension cable components and the necessary stress prediction during this construction process. In fact, similar conclusions can be drawn based on professional mechanical analyses and test results, but this method simplifies the complex professional mechanical analysis process using the new construction industrialization platform. It also shows that the new construction industrialization platform constructed in this paper can provide a scientific decision-making basis for managers without the need for professional experience, reduce the threshold of application of professional technology, improve the degree of intelligence of construction safety analysis, and provide platform support for promoting the high-quality development of new construction industrialization.

To achieve dynamic cost management of construction, it is necessary to manage and monitor progress.On the one hand, effective control of the construction progress can effectively save the construction period, thus reducing the cost of labour, machinery and equipment, and at the same time, can be rewarded for early completion. On the other hand, increasing the progress of the dimensions of the control can be integrated to determine the resource input programme, and real-time control of the amount of resource input to reduce the waste of resources. For a bank in Fujian Province, for example, a comprehensive service building project, the use of this paper establishes a new construction industrialization platform to carry out project cost management analysis. Because manpower, materials, and machinery costs in the project construction account for a large amount, Table 4 shows the specific application of benefits as an example.

Construction cost management of engineering projects

| Application | Item | Budget cost | Actual cost |

| Personnel management | Norm number | 392417man-hours | 284152man-hours |

| Fixed manual | 82yuan/man-hours | 147yuan/man-hours | |

| Labor budget | 32178194yuan | 42231852 yuan | |

| Material management | Budget reinforcement | 10152t (4000yuan/t) Total:40608000yuan | 9042t (3800yuan/t) Total:34359600yuan |

| Commodity concrete | 46200m3 (420yuan/ m3) Total:19404000yuan | 41250m3 (360yuan/ m3) Total:14850000yuan | |

| Mechanical management | Tower crane | 3360000yuan | Introduce the intelligent and interforce mechanical management and find zero effectively, The fault of the parts, the overall service life of the equipment, the actual cost of the equipment is 8028340 yuan. |

| Pump car | 558000yuan | ||

| Excavator | 8150000yuan | ||

| Other | 803500yuan | ||

| Total Cost | 105061694yuan | 99469792yuan | |

In terms of front-line construction personnel costs, the total overrun was 10053658 yuan, mainly because the actual labor unit price was higher than the quota and the cumulative labor price difference was higher than the cumulative saving amount per working day, but the fixed number of working hours was reduced from 392417 to 284152. Complete information on labor personnel, improve management efficiency, shorten the time of personnel counting, and improve the efficiency of labor resource utilization. In addition, the project team that completed the project ahead of schedule can be transferred to the new project in advance, which can save labor management costs to a certain extent, and the cumulative labor overrun is about 10 million yuan. Using the new building industrialization platform to reduce waste through strict control of the quota picking, the project is equivalent to saving 10802400 yuan in material savings and at least about 4843160 yuan in mechanical costs after the completion of the whole project. In addition to the part of manual overrun, the project carried out through the new building industrialization platform can save about 5 million yuan after completion, can effectively improve the efficiency of labor resource utilization and management, and also provide support for promoting the intelligence of the project.

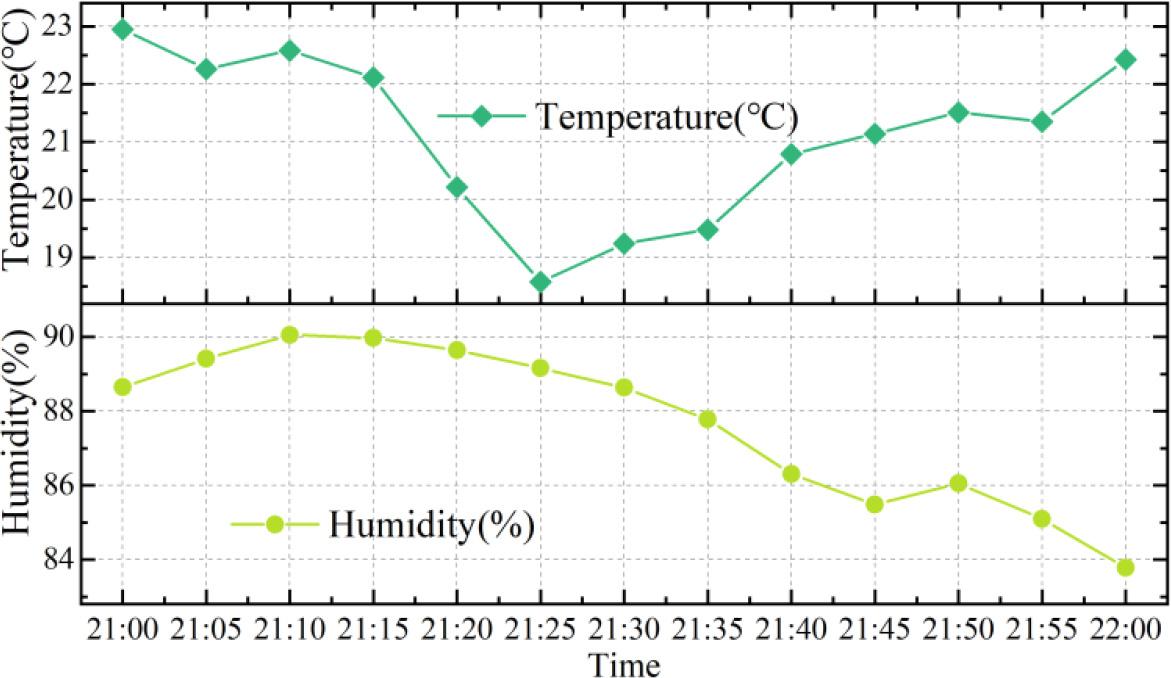

One environmental monitoring terminal is arranged with the upper wall at the entrance of the curing box at the engineering site to collect the temperature and humidity information of the curing box, and another environmental monitoring terminal is arranged at the wall of the first-floor façade of the construction site to collect the environmental information of the construction site. The results of the temperature and humidity monitoring of the engineering equipment are shown in Figure 7. The real-time equipment information collection function of the new construction industrialization platform helps project managers quickly understand the temperature and humidity changes of the engineering equipment and the environmental changes of the construction site. Then, according to the construction site temperature and humidity, reasonable project progress adjustment fully guarantees the service life of engineering equipment and the working environment of the construction site personnel in order to enhance the efficiency of the project to lay a solid foundation.

Temperature and humidity monitoring of engineering equipment

This paper combines BIM technology and digital twin technology to establish a new construction industrialization platform, relying on the new industrialization platform to promote the high-quality development of new construction industrialization. The neighborhood iterative search algorithm is introduced into the platform for constructing rectangular pieces sampling optimization, and the average and worst utilization rates of building panels are 0.908 and 0.737, respectively, which are 7.08% and 15.52% higher than that of the BFP algorithm. The utilization rate in the actual cutting and sampling of building materials can reach 96.79%, and the sampling time for different kinds of rectangular building materials is only 489.5 s. Additionally, the platform connects to digital twin technology, enabling intelligent analysis of key construction components. It calculates the EV value of component nodes to accurately reflect the safety conditions of construction, thereby enhancing the personal safety of construction personnel. By relying on the platform for intelligent scheduling of personnel, materials, and machinery, it can effectively reduce project costs by approximately 5 million yuan. Additionally, it enables real-time monitoring of engineering equipment, temperature, and humidity at the construction site, providing technical support to enhance the service life of the equipment and the on-site construction environment.

Combining BIM technology and digital computing technology to build a new construction industrialization platform can serve as a development path to enhance the level of construction industrialization. This approach can also effectively enhance the quality of new construction industrialization development, thereby improving the level of regional economic development.

This work was supported by the Doctoral research start-up fund of Zhangzhou Institute of Technology (NO. ZZYB2302), the Education System Philosophy and Social Science Research Foundation of Fujian Province (NO. JAS22323), and also the Science and technology teachers research and innovation team fund of Zhangzhou Institute of Technology (NO. zzyt23009).